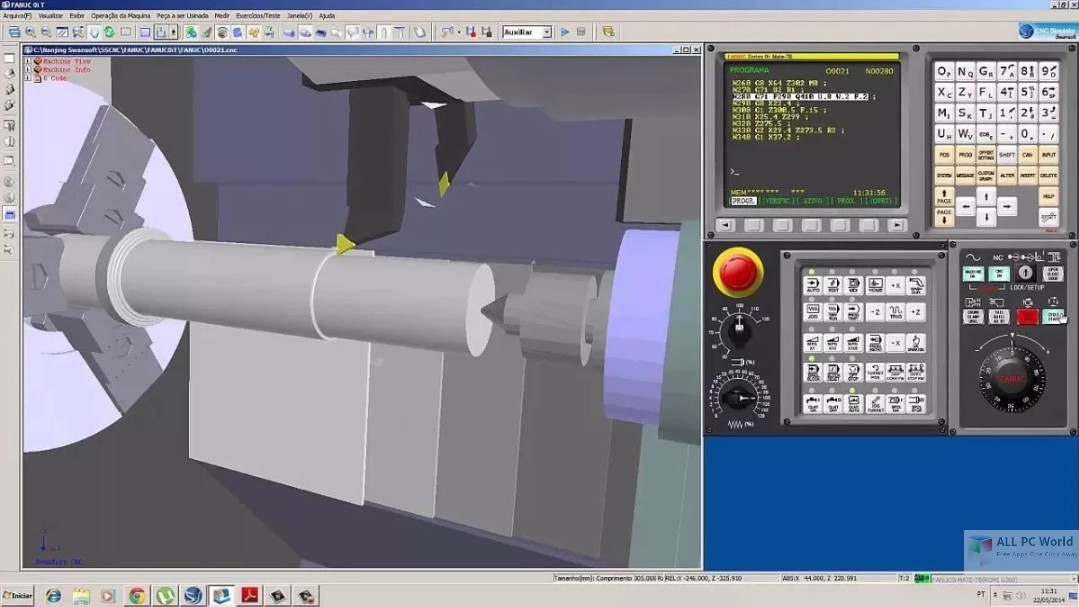

The FANUC Machining Simulator features Autodesk Fusion 360 CAD/CAM/CAE software and a custom machining simulation program designed by ModuleWorks. The FANUC Machining Simulator encompasses the complete manufacturing process from part design and engineering to CNC programming to virtual production simulation. Equipped with the same manual pulse generator and emergency stop button as the real machine tool.Easy to understand simple system configuration for beginners.

FANUC’s MANUAL GUIDE i conversational programming interface allows user to graphically generate programs that can be simulated in 3D, prior to being converted back to conventional NC programs and used on machine tools using FANUC controls. The Simulator is an actual FANUC CNC control, so students will become familiar with the look, feel, function and layout of the control as they navigate and program a fully operational CNC control.

The FANUC CNC Simulator is based on the FANUC Series 0i – MODEL F platform and can be started up in either milling or turning configurations. Students learn how to get the job completed in the shortest time possible and focus on machine operations, rather than just G-code, providing students with exposure to FANUC CNC controls without the need for a full machine. For students advancing to a smaller job shop or tool room, MANUAL GUIDE i simplifies programming.

0 kommentar(er)

0 kommentar(er)